| Machine position | Eight position |

| Pouch material | Laminated film\PP\PE etc. |

| Packing Speed | 20-60bags/min |

| Bag Size | (L)100-300mm (W) 70-200mm |

| Filling Volume | 10-1000g |

| Accuracy | ≤±1% |

| Dimension | (L)1900 * (W)1570 * (H)1700 |

| Work flow | Giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

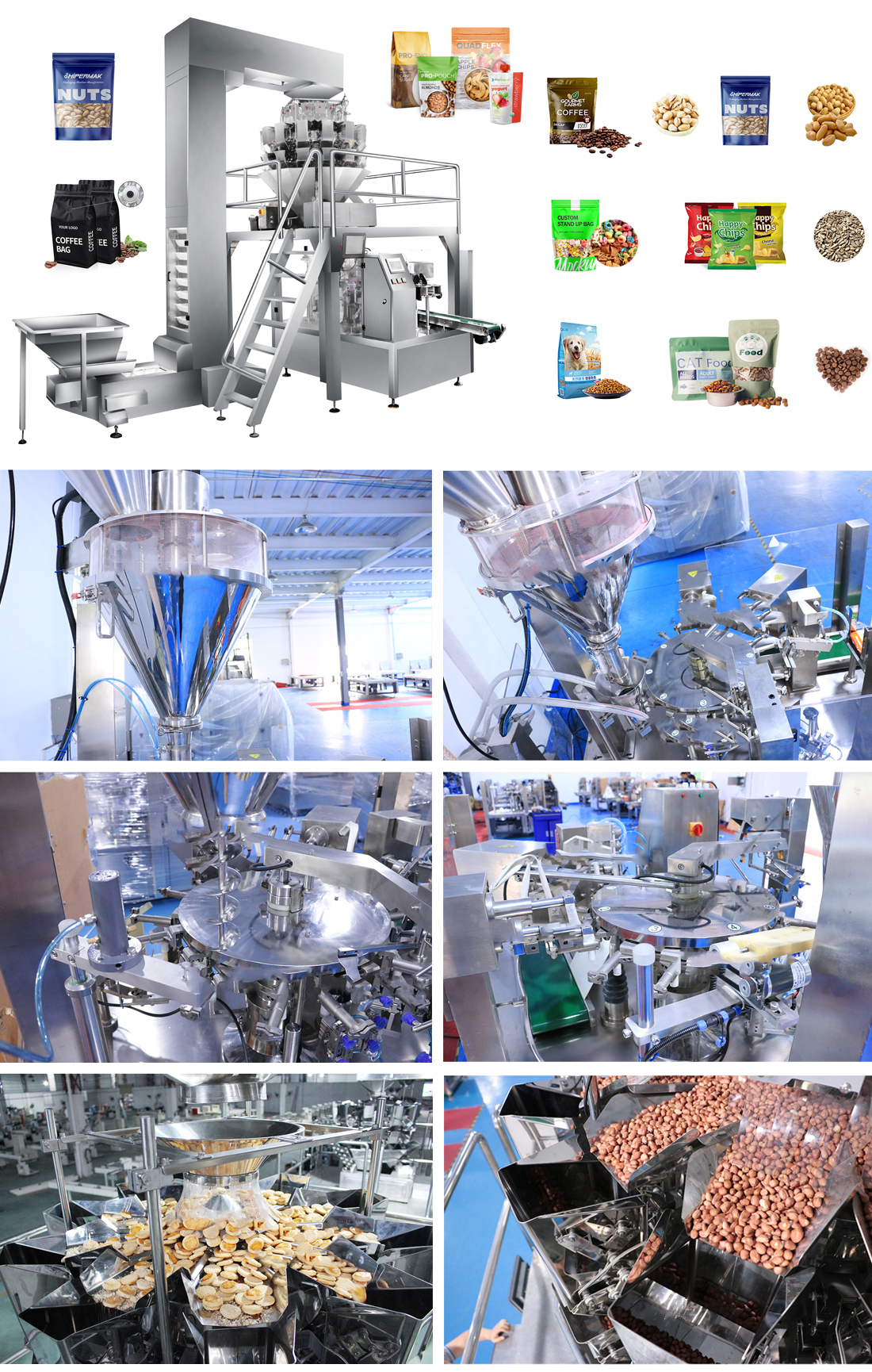

Applicable scope

1. Block material: bean curd cake, fish, eggs, candy, cereal, chocolate

2.Granular type: seeds, sugar, chicken essence, melon seeds,nut

3. Powder type: milk powder,washing powder, fine white sugar

4. Liquid/paste type: rice wine, soy sauce, fruit juice, beverage, tomato sauce, peanut butter, jam

Main standard parts

1.Code printer 2. PLC control system 3. Bag opening device 4. Vibration device 5. Cylinder 6.Electromagnetic valve7. Temperature controller 8. Vacuum pump

1. Block material: bean curd cake, fish, eggs, candy, cereal, chocolate

2.Granular type: seeds, sugar, chicken essence, melon seeds,nut

3. Powder type: milk powder,washing powder, fine white sugar

4. Liquid/paste type: rice wine, soy sauce, fruit juice, beverage, tomato sauce, peanut butter, jam

Main standard parts

1.Code printer 2. PLC control system 3. Bag opening device 4. Vibration device 5. Cylinder 6.Electromagnetic valve7. Temperature controller 8. Vacuum pump